Turning Your Great Idea into a Great Product

Launching a new electronic product takes more than a good idea — it requires the right expertise to turn that idea into something manufacturable, scalable, and reliable at volume. At SEACOMP, we offer engineering services as part of our full product development and manufacturing solution: because our goal isn’t just to design your product, but to help you successfully build it.

We design with production in mind from the start. Our in-house engineering team (spanning hardware, firmware, mechanical, and electrical disciplines) works hand-in-hand with you to define technical requirements, solve complex challenges, and ensure your product is ready for the rigors of high-volume manufacturing. From early development through to final assembly, we optimize for quality, consistency, and repeatability.

Design Engineering Services

- Product Development

- Electrical Hardware Design

- Mechanical Design

- Embedded Software Design

- New Product Introduction (NPI)

- Test Fixture Design

- Design for Supply Chain

Engineering Services

Hardware Design

Unlock your product’s full potential with consistent, reliable performance through our electrical engineering expertise. We support your product development with schematic design, PCB layout, PCB testing, IC component selection, and more.

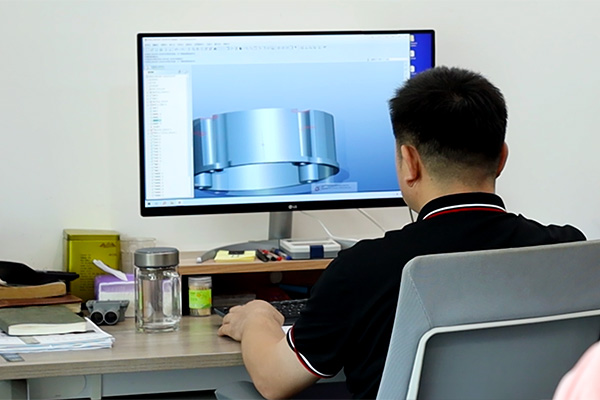

Mechanical Design

Your product deserves mechanical engineering that delivers on fit, function, and future growth. Our engineers optimize your design with prototyping, enclosure design, 3D modeling, and injection tooling development to guarantee your product is ready for repeatable builds.

Embedded Software Design

Confidently build your product with embedded software designed for reliability and connectivity. Our team specializes in firmware development, microcontrollers and microprocessors (Bare Metal, RTOS, OS), and wireless communication.

Preparing Your Design for Mass Production

Reduce Production Risks with DFM

Design for Manufacturability

Our design for manufacturing (DFM) process is baked into every project we work on. We evaluate your design for production readiness, identifying opportunities to simplify assembly, reduce component costs, and improve yield. By catching potential issues early, we help you minimize revisions, shorten timelines, and scale more efficiently.

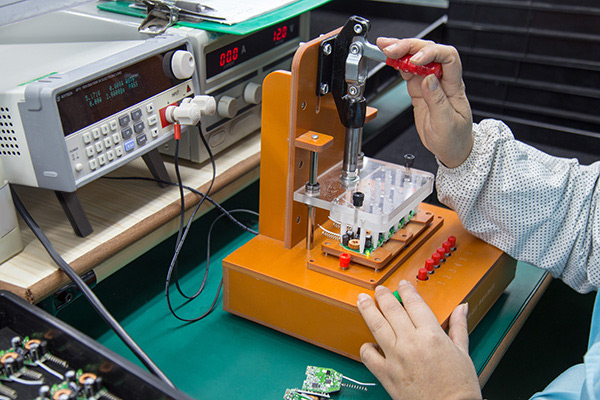

Tested to Perfection

Test Fixture Design

We design custom test fixtures specific to your product that streamline and automate testing during manufacturing. These fixtures are built around your specific product, allowing for efficient in-circuit testing, programming, and functional checks. With our PCB test fixtures and end-of-line test fixtures, you'll maintain consistent quality across every unit shipped.

EVT + DVT

Validation Testing

We support your product through engineering validation testing (EVT) and design validation testing (DVT) to ensure it performs as intended before entering mass production. Our engineering and production teams handle comprehensive validation protocols based on your product requirements to confirm functionality and reliability. With thorough validation testing, any issues are identified and corrected early on so that you have a strong foundation to successfully manufacture your product at scale.

Design Engineering Services

New Product Introduction

Bring your product to market with design engineering that aligns every detail to mass production. From early development through DFM/DFA to certification, SEACOMP is your partner that helps set your product launch up for success.

Wireless Design and Development

Enable seamless connectivity with wireless design that’s built for performance and reliability. We support your design by integrating Wi-Fi (IEEE 802.11), Bluetooth, or other wireless protocols along with managing certifications such as FCC.

Design for Supply Chain

Designing for longevity starts with smart component choices. We analyze your BOM for long-term validation and sustainable pricing. We also support in sourcing for component replacement and LCD selection. All with the goal of keeping your product buildable for years to come.

BMS and Embedded Circuit Design

Powering Your Device

Our engineering team thinks early on about how to power your design - as this can affect performance, safety, and efficiency of your device. We offer a suite of certified AC-DC power supplies, charging systems with rechargeable batteries, and charging cables that can be customized to fit your product requirements.

Learn MoreTrusted by these Brands