Many of the “successful” crowdfunded hardware campaigns (Pebble, Coolest Cooler, ZPM Espresso, etc.) started out with a bang and ended in a slow, painful death brought about by a series of decisions gone awry. The problem is that these companies didn’t have enough information, or experience, to know what they didn’t know. Many of these failures could have been avoided altogether, or at least minimized, with some insight into the pitfalls that lie ahead for all hardware new product introduction (NPI) processes. Here are some recommendations for planning your new product development strategy.

Set a Game Plan for your New Product Introduction

Unrealistic expectations or misalignment between teams creates a hostile environment for NPI and has been the downfall of many crowdfunded hardware companies. The right people on the right teams need to be involved in the decision-making process early and be in total agreement with the product features, cost and launch timeline.

The right people on the right teams need to be involved in the decision-making process early and be in total agreement with the product features, cost and launch timeline.

Conflicts between sales, engineering, supply chain and quality can make the NPI process more difficult than it needs to be. Often the sales team is out selling a product before the engineering team has even finished development (which is almost always the case with crowdfunding). This situation puts pressure on engineering to rush development. In turn, the supply chain and quality teams are forced take on increased risk to hit an unrealistic timeline for a product that still has many unknown variables. Worst of all, the end customer, who already pre-ordered the finished product, gets frustrated waiting for something that repeatedly gets delayed. This dynamic of misalignment and an unrealistic game plan creates multiple risk and reward decision points that combined decrease the chances of a successful NPI.

Timing of NPI Design Changes

Once the features, cost, and launch date have been agreed upon, teams should set a very high bar for altering the game plan. For example, new product features should only be added if it is compulsory. Compulsory reasons generally are derived externally. Examples include regulatory or safety compliance or if a major customer will only purchase the product if a certain design change is made.

In the absence of a solid game plan, “feature creep” can become a real challenge and can happen for a number of reasons. Feature creep is when features are added intermittently throughout product development. Sometimes features are added because insufficient market research was done up front. Other times, a CEO or marketing exec simply wants to add a new feature late in the process. No matter the reason, strategies for dealing with feature creep and a decision matrix for what does or does not get added must be agreed upon up front. Any feature categorized as a “nice to have” should be added to the list for Product 2.0 so as not to jeopardize the successful launch of Product 1.0 as already agreed upon.

Teams should set a very high bar for altering the game plan.

If a change must be made to the design, make it as early as possible. There is an exponential increase in cost and complexity the later you are in the product development process1.

Additionally, a drop-dead date for no longer adding new features must be decided upon. The need to generate revenue may far exceed the need for adding a feature to the product. If your company can survive the startup phase, there will be an opportunity to create a second generation device with more features than the original. However, if your company goes out of business due to lack of revenue, it won’t matter how great your product is since you won’t be around to sell it.

During the development phase, there are design strategies for maintaining flexibility in options for as long as possible. The longer you want to maintain options however, the more expensive the product can get. There is a point when it becomes necessary to make a clear decision to hit your cost or delivery target. The longer that decision gets put off, the risk of missing targets for cost or launch dates increases.

Design Verification and Design For Manufacturing within NPI

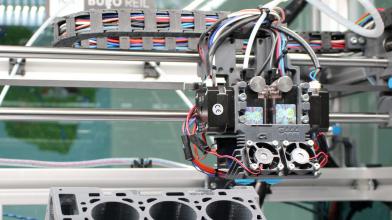

Most hardware projects that fail have a combination of design and manufacturing challenges. Some companies simply could not get the technology to work as promised or to work at a price point that made the product viable. Even if the technology worked properly, many designs were not manufacturable at volume (prototyping and 3D printing are NOT the same as mass production). The DVT and DFM are important phases and are absolutely critical to the success of a project. These phases should be formalized and have objective review before investments are made in tooling or material procurement.

Additionally, the need for programming and test fixtures for mass production are often overlooked or not included in the overall product development timeline. A good CM or EMS partner will address this need early in the NPI process to ensure that the quality of the product will be maintained as volumes ramp up while also adhering to the overall schedule requirements.

Risk Management and New Product Introduction

Accurately assess the risk of your NPI strategy and understand where and with whom the risks lay. An engineering firm or contract manufacturer is typically not in the business of taking risk on your behalf. If your NPI plan is loosely defined and you also have an aggressive timeline, be prepared to put money down up front to fund the risks that you must take to hit your launch date. Expecting a contract manufacturer to invest their own resources to fund your risk is not a winning strategy. This situation often leads the CM or ODM partner to make claims of IP ownership on your product since they have invested resources into getting to production. Ensure that you follow the correct steps to protect your IP.

Understand the Consequences of Late Delivery of your NPI

One common theme for crowdfunded hardware projects is the dreaded update from the founders detailing the latest problems that they have run into that will cause yet another delay. In these cases, the early backers of a product grow restless and begin to lose confidence in the ability of the founders to deliver on the promise from their fundraising video.

As a result, a vocal crowd of frustrated reviewers leave angry messages, tweets, and Facebook posts about how disappointed they are with the company before it has even gotten off the ground. The resulting bad press may prove too much to overcome for fledgling companies. Working with a company that has experience with NPI will help set realistic expectations and keep your backers from turning against you.

Some projects have more than backers from their Kickstarter or Indiegogo campaign to consider. Some startup companies will have real purchase orders from large retailers that are contingent upon delivery of a certain number of units by a certain date. In this case, the consequences of late delivery can be daily late penalty fees or even orders that are cancelled altogether. If this happens, a startup company may find that they suddenly no longer have a customer and have committed to a production inventory. Now the company has inventory that they likely cannot sell before needing to pay the manufacturer for the finished goods. This is typically the beginning of the end for a company in that position.

Minimize risks and missing targets with a well-planned NPI strategy. Use the above new product introduction best practices as a starting point. Every industry, product and team will have its own particular set of challenges that an experienced partner can help you navigate. Choose an EMS partner that has the services available to complement your own teams’ strengths.

Hardware can be hard, but it doesn’t have to be. When thinking about your NPI process, remember this saying, “Slow is smooth. Smooth is fast.”