Manufacturing Made Better

At SEACOMP, we focus our energy where it matters most—helping you bring your product to life with a seamless, collaborative process. When every stage of development is supported by an aligned team, the journey to mass production becomes more efficient and ultimately, more successful.

Our holistic approach to electronics manufacturing removes unnecessary hurdles, so you can spend more time innovating and less time managing complexity. We’re not just here to build your product—we’re here to bring excitement, expertise, and momentum to the process. Let’s create something impactful, together.

Benefits of Working with SEACOMP

- Expert guidance and collaboration to identify roadblocks early on

- Rigorous quality control at every stage of the production process

- Customizable processes to meet your product's unique needs

- Strict IP protection for your product design

- Clear and efficient communication

Electronic Product Design

Enhance your product with our expert engineering services, optimizing for performance, manufacturability, and scalability. With in-house engineering, prototyping, and DFM support across the US, Europe, and Asia, we refine your design for mass production with our proven NPI process and testing capabilities.

Turnkey Manufacturing

Simplify your hardware product development from concept to production. Integrate your design and manufacturing into one process, and let us coordinate your path to mass production. Our complete turnkey solution is designed to make your life easier.

Product Focus

Electronics Manufacturing Services Overview

Manufacturing & Supply Chain Setup

Over our 30+ years of experience, we have helped scale electronic devices for mass production. Our team manages procurement, tooling, and factory preparation — optimizing for cost, quality, and lead time. We handle the details so you can focus on your product.

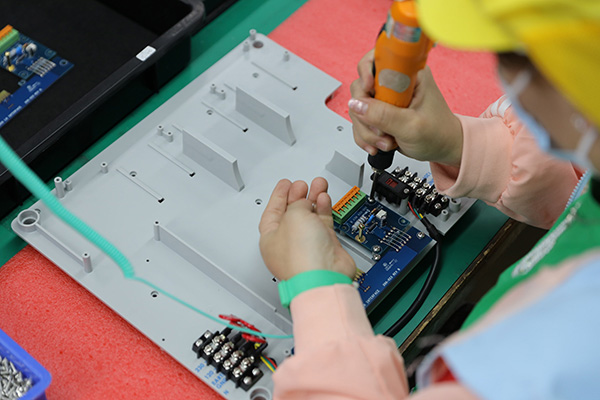

Quality Assurance

Every stage is carefully managed to refine your product before full-scale manufacturing. With rigorous in-line inspections, functional testing, and adherence to global certifications, we guarantee your product meets the highest quality standards.

Finished Assembly

We tailor our contract manufacturing to your needs. We handle packaging, labeling, and logistics, ensuring your product is delivered worldwide — ready for market, every time.

Certifications

ISO13485:2016

ISO9001:2015

MFI Authorized

Discover our Mexico Facility

Our Tijuana, MX facility offers 60,000 sq. ft. of manufacturing capability just an hour’s drive from our HQ in Carlsbad, California. Manufacturing your product in Mexico offers ample possibilities for in-person collaboration.

Electronics Manufacturing in Mexico

Manufacture Your Device in Tijuana, MX

Our new manufacturing facility in Mexico offers an unmatched opportunity to diversify your supply chain, reduce costs and lead times, and build confidence in your go-to-market plan. Mexico’s close proximity to other North American businesses promises increased opportunities for "hands-on" collaboration, enabling faster design-to-production knowledge transfer and easier problem-solving.

Inside our MX Factory

About our China facility

Our Southeast China manufacturing campus features a 5-story, 11,000-square-meter building for PCB assembly, plastic injection molding, final assembly, and warehousing. We invite customers to visit this facility for due diligence and during important phases of NPI.

Electronics Manufacturing in China

High Volume Production in Dongguan, China

Our China manufacturing facility is in the heart of the electronics manufacturing capital of the world. In addition, we’ve intentionally set our own factory’s supply chain to remain local within the area. This means we are able to procure components faster, avoid potential transport or customs delays, and can keep quality control in check. By staying local, we’ve simplified sourcing complexities that often are found with manufacturing in China. This makes launching your product more efficient, enjoyable, and successful for everyone involved.

Inside our CN FactoryWho We've Worked With