Spanning an impressive 60,000 square feet, the new facility will serve as a hub for turnkey manufacturing services, encompassing design engineering, PCB assembly, plastic injection molding, product testing, final assembly, and packaging. Located just an hour south of SEACOMP’s Carlsbad headquarters in Southern California, our new plant will help meet the diverse needs of our customers creating medical, consumer, and industrial devices.

"Manufacturing is a global industry, but it’s also a hands-on business. That’s why we’ve made the decision to bring most of our leadership team back together under one roof and introduce a new SEACOMP facility just an hour away from our command center in Southern California," says SEACOMP CEO, Michael Szymanski.

Mexico’s close proximity to other North American businesses promises an unmatched opportunity to diversify product supply chains, reduced costs and lead times, and provides increased possibilities for “hands-on” collaboration throughout the product development process.

Grand Opening Event

The team celebrated the factory’s opening May 9, 2024, with an official ribbon-cutting ceremony, facility tour, and networking opportunities for 115 executives, partners, global team members and customers.

Watch a recap here:

Community Impact

SEACOMP will create a total of 100 jobs in 2024, with about a third of those being highly skilled roles in engineering and management.

“We feel that [with] putting together our talent and economies, we can make a very strong [Cali Baja] region.” - Cristina Hermosillo, President of Desarrollo Económico e Industrial de Tijuana (DEITAC)

Facility Development

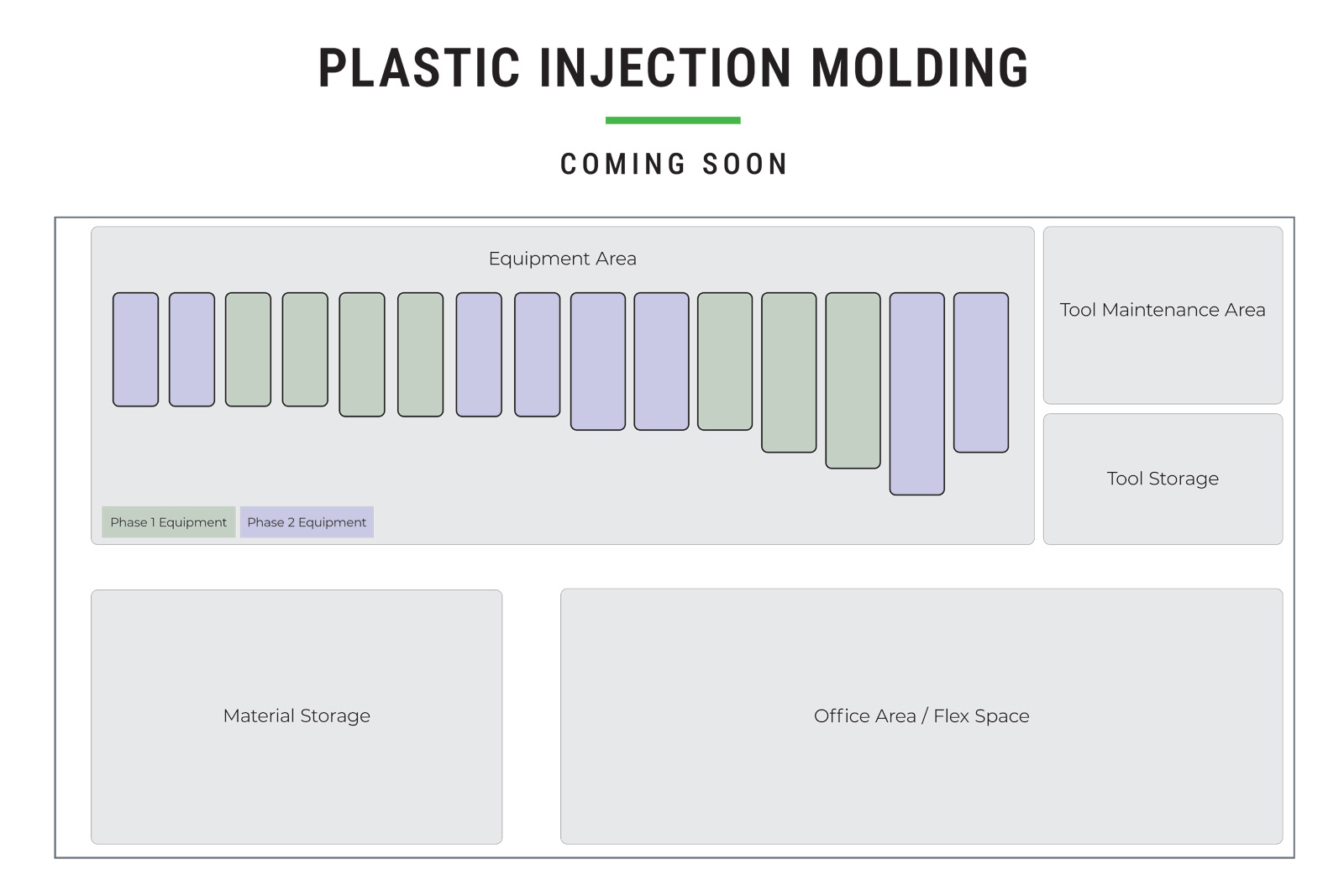

Plastic Injection Molding

We are taking a phased approach to completing our plastic injection molding set-up in Mexico. Used to create strong, high-quality parts, plastic injection molding is a manufacturing process known for its flexibility, efficiency, and cost-effectiveness. Here’s our plan for setting this up in our new facility:

Certifications

Our facility in China is fully equipped with the best-in-class manufacturing certifications, and soon our Mexico manufacturing plant will be too. Beyond standard safety and compliance certifications, SEACOMP goes the extra mile to help your product excel in quality and reliability. We are on track to achieve the following certifications by the end of 2024:

- ISO 9001:2015

- ISO 13485:2016

- Apple MFI Authorization

Nearshoring Benefits

Closer to Home (or to your customers), Faster to Market

Mexico’s close proximity to other North American businesses promises shorter lead times and increased opportunities for "hands-on" collaboration, enabling faster design-to-production knowledge transfer and easier problem-solving.

Save on Tariffs with USMCA

Thanks to the US-Mexico-Canada Agreement (USMCA), formerly NAFTA, manufacturing in Mexico is not only practical but also economically advantageous. By manufacturing your product in Mexico, you’ll find reduced tariffs compared to other overseas production locations, offering you cost savings while supporting local trade relationships.

Just-in-Time-Zone-Manufacturing

Benefit from faster responses to any questions with a manufacturing partner that shares your business hours. The nearshore proximity means you can collaborate more closely with our facility’s engineering and production experts, accelerating your timelines.

"Our expansion into Mexico represents a strategic milestone for SEACOMP," said Mike Szymanski, CEO of SEACOMP. "This investment not only strengthens our global presence but allows us to better serve our customers with end-to-end support in a manufacturing location that is highly desirable."

Ready to start the conversation about nearshoring your product? Get in touch to bring your product closer to home!